Volvo Guide to Haldex fault finding, ECU repairs and replacement

The part numbers we see often are:-

| Volvo hap511 5wp22201-01 (Gen 2) Volvo hap511 5wp22201-02 (Gen 2) Volvo hap511 5wp22201-03 (Gen 2) Volvo hap511 5wp22201-04 (Gen 2) Volvo hap511 5wp22201-05 (Gen 2) Volvo hap511 5wp22211-01 (Gen 2) Volvo hap511 5wp22211-02 (Gen 2) Volvo hap511 5wp22220-01 (Gen 2) Volvo hap511 5wp22227-01 (Gen 2) Volvo hap511 5wp22228-02 (Gen 2) Volvo hap511 5wp22229-01 (Gen 2) Volvo hap511 5wp22245-01 (Gen 2) Volvo hap511 5wp22246-01 (Gen 2) |

Volvo hap542 5wp33502-01 (Gen 3) Volvo hap542 5wp33512-01 (Gen 4) |

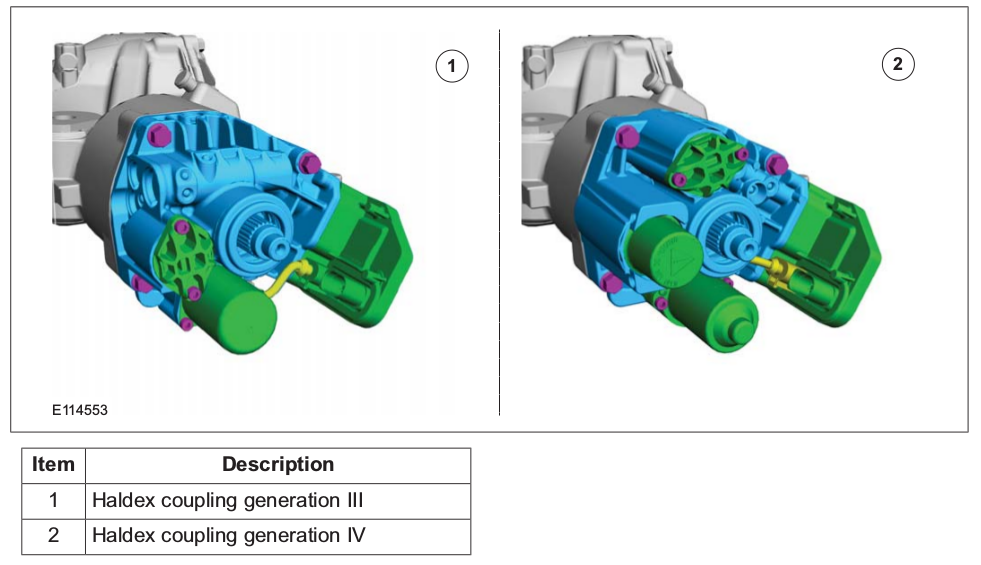

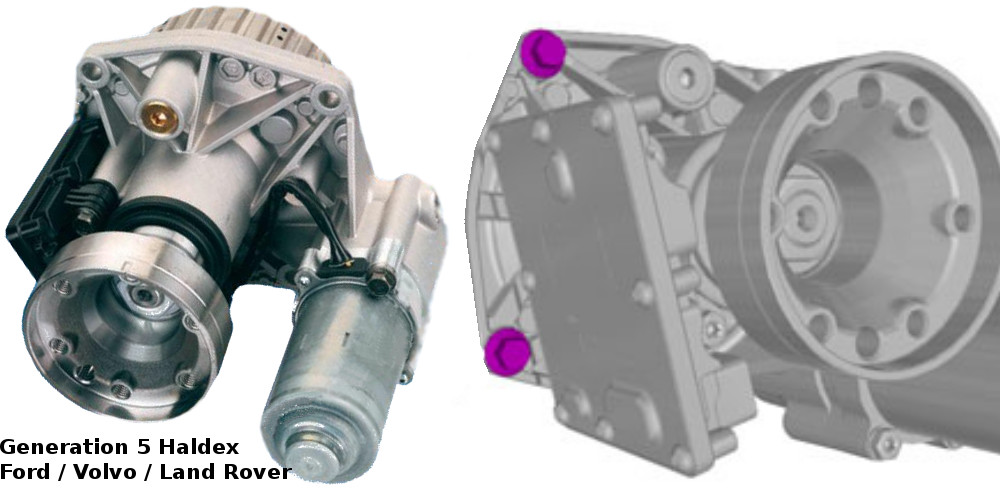

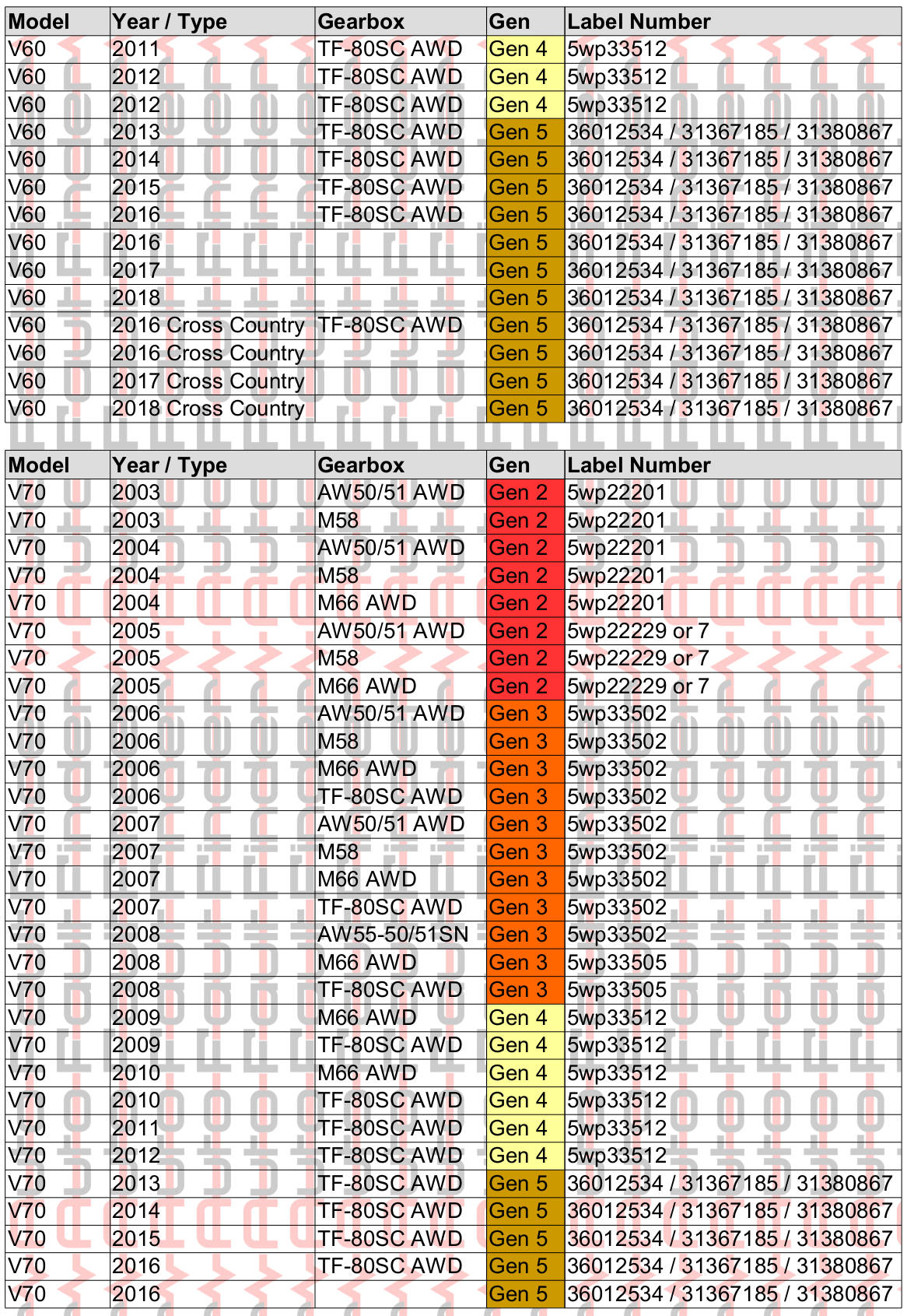

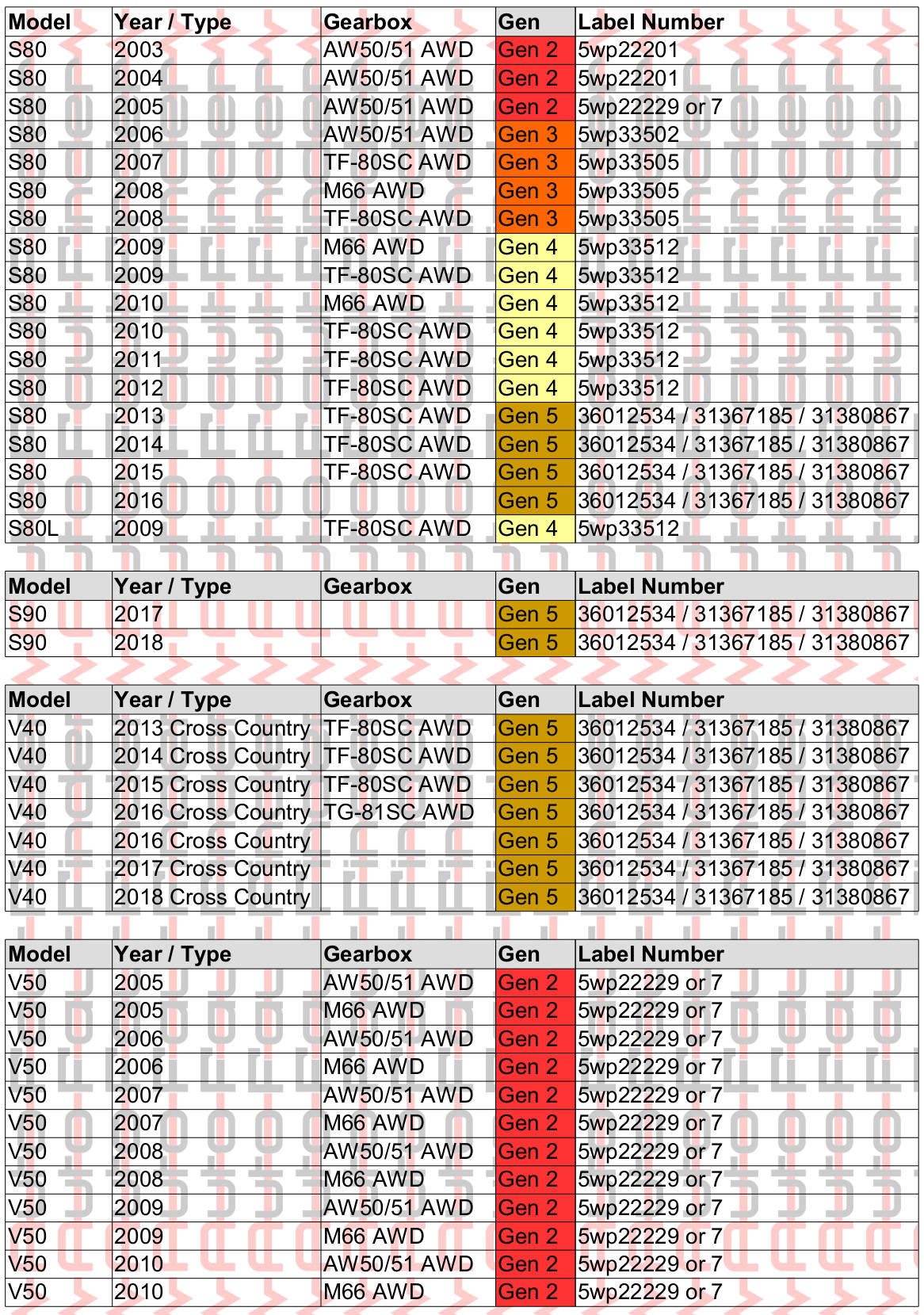

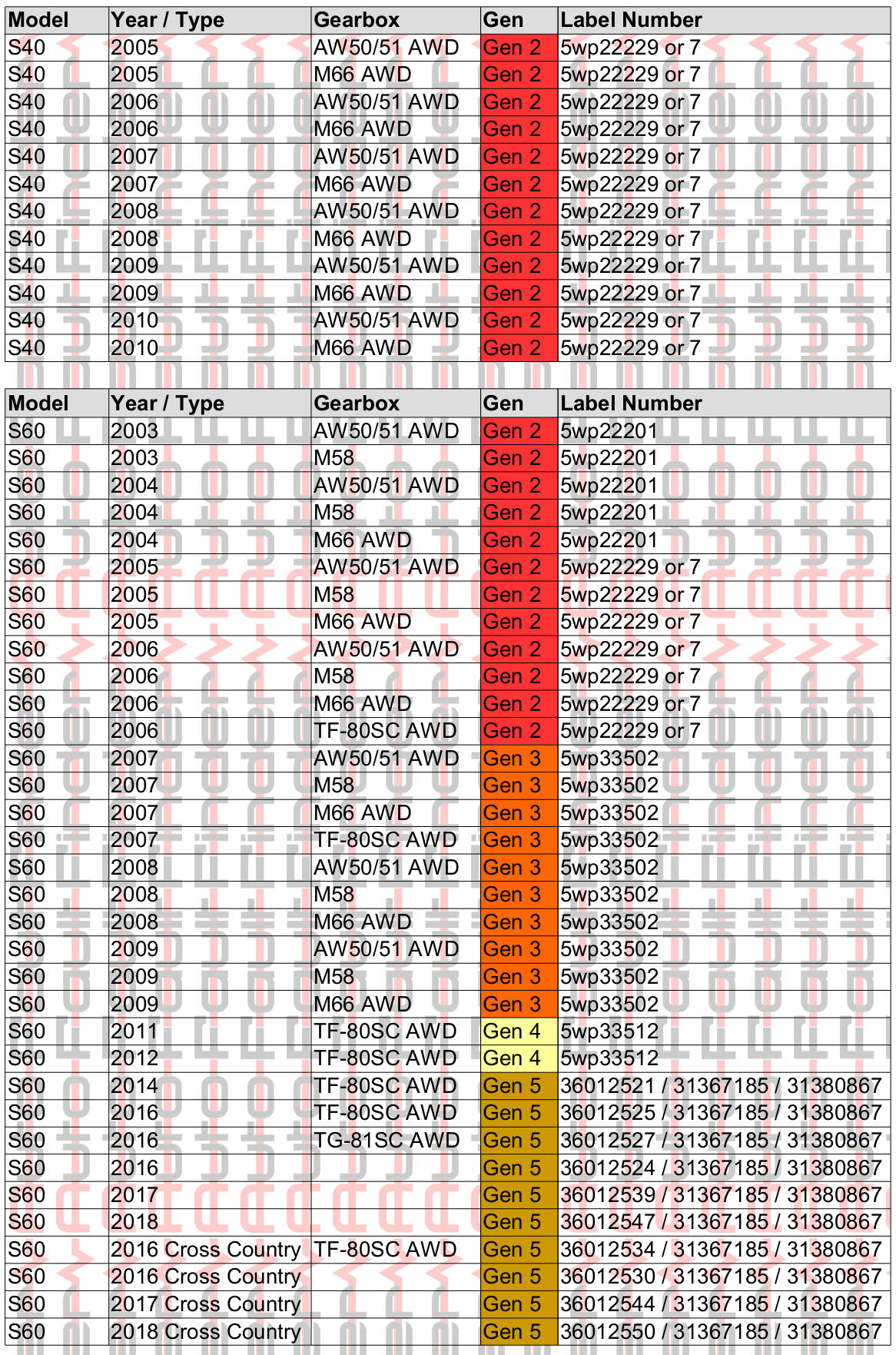

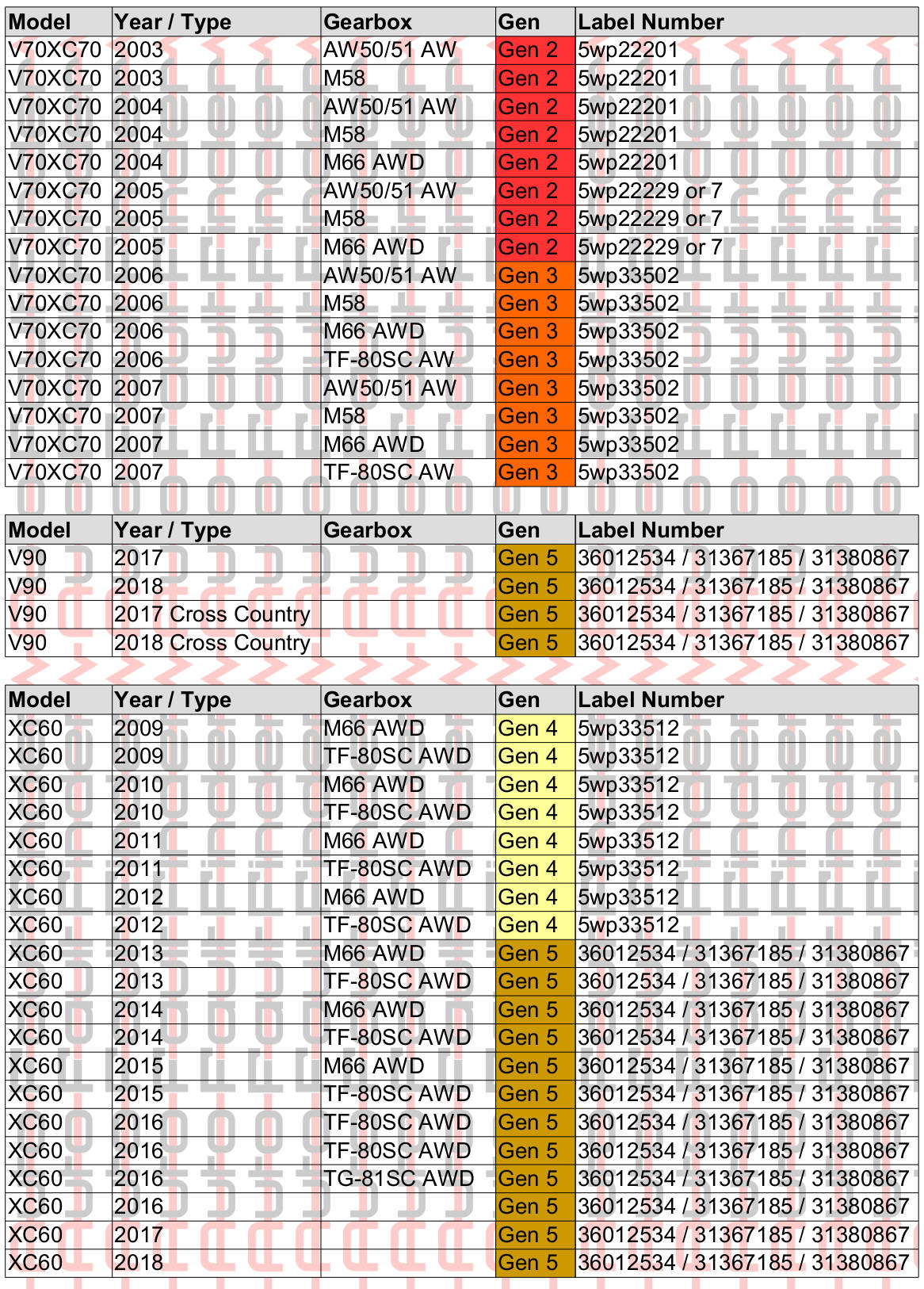

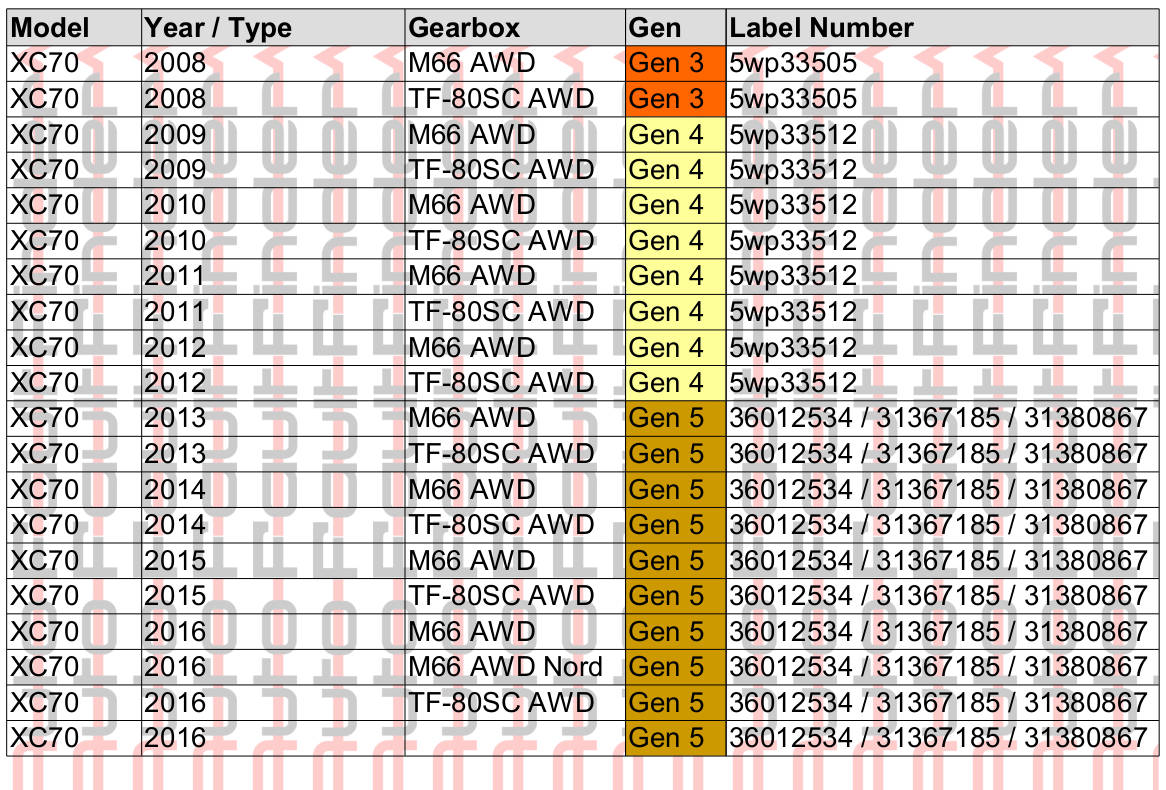

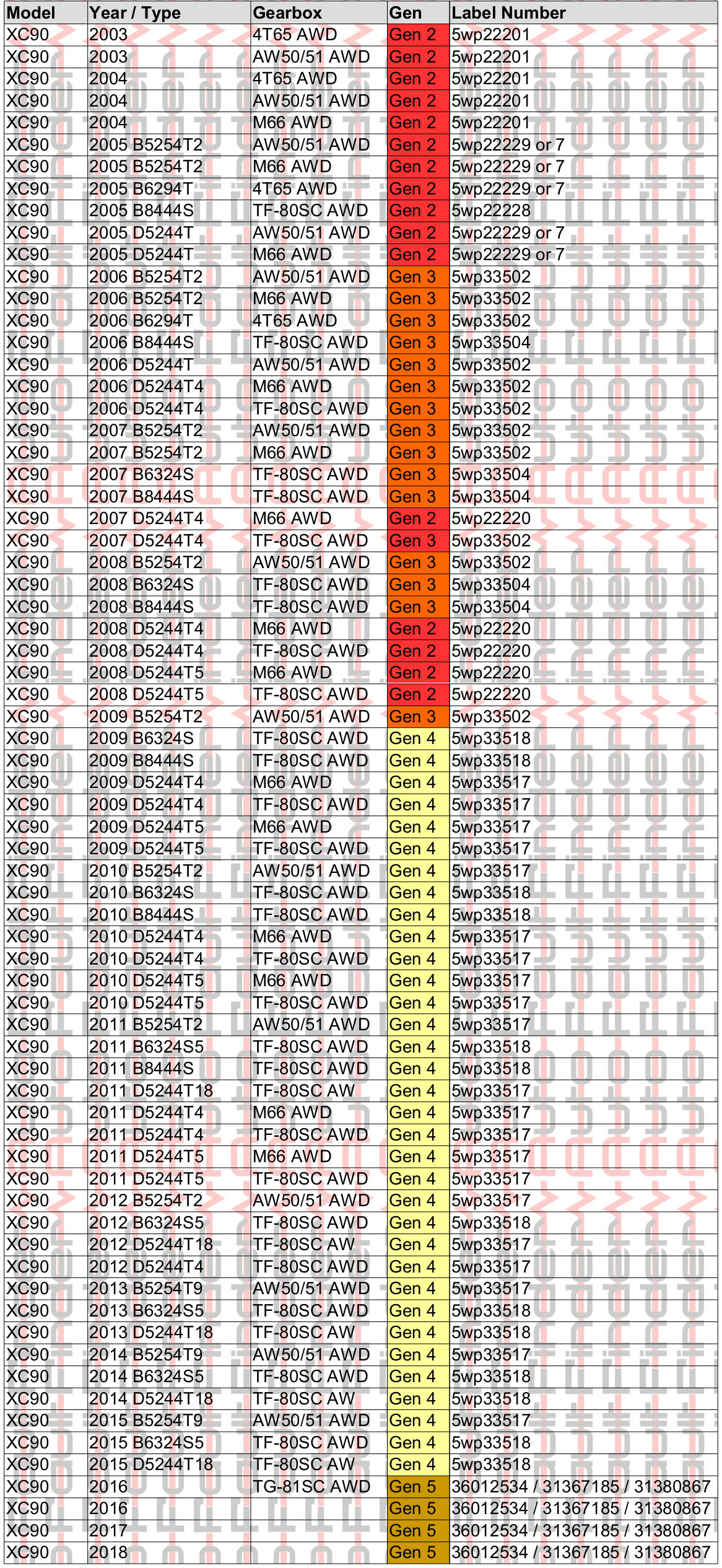

What Generation of Haldex is on what Volvo model?

(This list is a guide only, see the image table below)

Generation 2 – HAP511 – Volvo DEM Part Number 36001750 was 30787954 was 30713310

Volvo S40 2005 – 2010 Volvo S40

Volvo V50 2006 – 2010 Volvo V50

Volvo S60 2003 – 2006 Up to Chassis -522546 (Last 6 digits of VIN)

Volvo V70 2004 – 2006 Up to Chassis -554316 (Last 6 digits of VIN)

Volvo S80 2004 – 2006 Up to Chassis -435568 (Last 6 digits of VIN)

Volvo XC70 2003 – 2006 Up to Chassis -220976 (Last 6 digits of VIN)

Volvo XC90 2004 – 2006 Up to chassis -257057 (Last 6 Digits of VIN)

Generation 3 Volvo DEM Part Number 36001751 was 30783061 was 30713163 was 30759702

Volvo S60 2006 – 2009 After Chassis 522547- (Last 6 digits of VIN)

Volvo S80 2006 – 2008 After Chassis 335000- (Last 6 digits of VIN)

Volvo V70 2006 – 2008 After Chassis 554317- (Last 6 digits of VIN)

Volvo XC70 2006 – 2008 After Chassis 220977- (Last 6 digits of VIN)

Volvo XC90 2006 – 2008 After Chassis 257058 till 494999 (Last 6 digits of VIN)

Generation 4 Volvo DEM Part Number 36001750 was 30787954 was 30713310

Volvo S60 2010 – 2012 (pre 2013 facelift) Chassis 000194-115694 Build dates 2010w20-2011w48

Volvo V70 2008 – 2012 (pre 2013 facelift)

Volvo S80 2009 – 2012 (pre 2013 facelift) Chassis 087101-157261 Build dates 2008w20-2011w48

Volvo XC60 2009 – 2012 (pre 2013 facelift) Chassis 018829-288205 Build dates 2009w05-2011w48

Volvo XC70 2008 – 2012 (pre 2013 facelift) Chassis 047601-132422 Build dates 2008w20-2011w48

Volvo XC90 2008 – 2014 (Mk1) Chassis 495000 onward Build dates 2008w20-2011w48

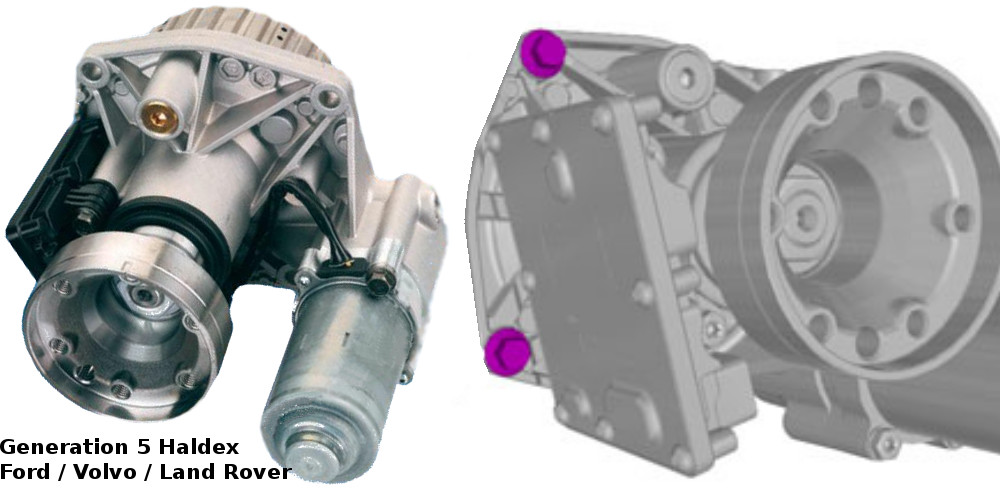

Generation 5 Volvo DEM Part Number 36012520 ex 31367185 ex 31380867

Volvo V60 & Cross Country 2015 onwards

Volvo V70 2013 onwards (facelift type)

Volvo S60 2013 onwards (facelift type)

Volvo S60 Cross Country 2016 onwards

Volvo S80 2013 onwards (facelift type)

Volvo XC60 2013 onwards (facelift type)

Volvo XC70 2013 onwards (facelift type)

Volvo XC90 2015 onwards (Mk2)

Volvo DEM Haldex Control Unit Repairs and Testing

‘Anti-Skid Service Required’

It is common to get the “Anti Skid Service Required” message on the dashboard instrument cluster when there is an issue with the Haldex controller called the DEM (Differential Electronic Module) on Volvo vehicles. Common fault codes are DEM-0002 / DEM-0003 / DEM-0006 / DEM-0007 / DEM-0008 / CEM-1A64 / BCM-0095 / BCM-0094

DEM-0006 is normally a fault with the Pump, but sometimes can be caused by the control unit if the electronics that drive the pump fail.

DEM-0007 is often the pressure sensor, but sometimes can be caused by the pump or the control unit for the same reasons as DEM-0006

Volvo 30783079 and 8689664 Generation 2 and 3 Haldex Pump S40 S60 S80 V50 V70 XC70 XC90

Volvo 30783079 and 8689664 Generation 2 and 3 Haldex Pump S40 S60 S80 V50 V70 XC70 XC90

Volvo 31256757 Generation 4 Haldex Pump S60 S80 V70 XC60 XC70 XC90

Volvo 31256757 Generation 4 Haldex Pump S60 S80 V70 XC60 XC70 XC90

Volvo Generation 5 Pump for Rear Haldex Differential 31367750 31367749

Volvo Generation 5 Pump for Rear Haldex Differential 31367750 31367749

Follow this Youtuber’s journey on diagnosing this issue, and by sheer luck using our repair services!

Later Volvos Give Fault codes like these:-

DEM-P056017 System Voltage. General Electrical Failures. Circuit voltage above threshold

DEM-P060254 Powertrain Control Module Programming Error. System Programming Failures. Missing calibration

DEM-P060749 Control Module Performance. System Internal Failures. Internal electronic failure

DEM-P063468 PCM / ECM / TCM Internal Temperature Sensor Circuit. Algorithm Based Failures. Event information

DEM-P064F05 Unauthorized Software/Calibration Detected. General Failure Information. System Programming Failures

DEM-P066611 PCM / ECM / TCM Internal Temperature Sensor Circuit. General Electrical Failures. Circuit short to ground

DEM-P066615 PCM / ECM / TCM Internal Temperature Sensor Circuit. General Electrical Failures. Circuit short to battery or open

DEM-P066727 PCM / ECM / TCM Internal Temperature Sensor Range/Performance. General Signal Failures. Signal rate of change above threshold

DEM-P074812 Pressure Control Solenoid A Electrical. General Electrical Failures. Circuit short to battery

DEM-P07481D Pressure Control Solenoid A Electrical. General Electrical Failures. Circuit current out of range

DEM-P096162 Pressure Control Solenoid A Control Circuit Range/Performance. Algorithm Based Failures. Signal compare failure

DEM-P163568 Tire/Axle Out of Acceptable Range. Algorithm Based Failures. Event information

DEM-P188912 Oil Pressure Pump Performance. General Electrical Failures. Circuit short to battery

DEM-P188914 Oil Pressure Pump Performance. General Electrical Failures. Circuit short to ground or open

DEM-P188918 Oil Pressure Pump Performance. General Electrical Failures. Circuit current below threshold

DEM-P188919 Oil Pressure Pump Performance. General Electrical Failures. Circuit current above threshold

DEM-P188949 Oil Pressure Pump Performance. System Internal Failures. Internal electronic failure

DEM-P18897A Oil Pressure Pump Performance. Mechanical Failures. Fluid leak or seal failure

DEM-P188971 Oil Pressure Pump Performance. Mechanical Failures. Intermittent

DEM-P188974 Oil Pressure Pump Performance. Mechanical Failure. Actuator Slipping

DEM-U000100 High Speed CAN Communication Bus. General Failure Information. No sub type information

DEM-U010000 Lost Communication With Engine control module. General Failure Information. No sub type information

DEM-U012100 Lost Communication With Brake Control Module. General Failure Information. No sub type information

DEM-U014000 Lost Communication With Central electronic module. General Failure Information. No sub type information

DEM-U030000 Internal Control Module Software Incompatibility. General Failure Information. No sub type information

DEM-U030046 Internal Control Module Software Incompatibility. System Internal Failures. Calibration / parameter memory failure

DEM-U03004A Internal Control Module Software Incompatibility. System Internal Failures. Incorrect component installed

DEM-U030054 Internal Control Module Software Incompatibility. System Programming Failures. Missing calibration

DEM-U040168 Invalid Data Received from ECM/PCM A. Algorithm Based Failures. Event information

DEM-U041568 Invalid Data Received From Anti-Lock Brake System Control Module. Algorithm Based Failures. Event information

DEM-U210000 Initial Configuration Not Complete. General Failure Information. No sub type information

DEM-U210100 Control Module Configuration Incompatible. General Failure Information. No sub type information

DEM-U300362 Battery Voltage. Algorithm Based Failures. Signal compare failure

Some scanners will read the code like this instead:-

P0748-12 Pressure Control Solenoid A Electrical. General Electrical Failures. Circuit short to battery

P0748-1D Pressure Control Solenoid A Electrical. General Electrical Failures. Circuit current out of range

P0961-62 Pressure Control Solenoid A Control Circuit Range/Performance. Algorithm Based Failures. Signal compare failure

P1635-68 Tire/Axle Out of Acceptable Range. Algorithm Based Failures. Event information

P1889-12 Oil Pressure Pump Performance. General Electrical Failures. Circuit short to battery

P1889-14 Oil Pressure Pump Performance. General Electrical Failures. Circuit short to ground or open

P1889-18 Oil Pressure Pump Performance. General Electrical Failures. Circuit current below threshold

P1889-19 Oil Pressure Pump Performance. General Electrical Failures. Circuit current above threshold

P1889-49 Oil Pressure Pump Performance. System Internal Failures. Internal electronic failure

P1889-7A Oil Pressure Pump Performance. Mechanical Failures. Fluid leak or seal failure

P1889-71 Oil Pressure Pump Performance. Mechanical Failures. Intermittent

P1889-74 Oil Pressure Pump Performance. Mechanical Failure. Actuator Slipping

No Fault Codes Stored AND scrabbling or grabbing or skipping or jumping or locked diff sensation going round tight turns, on lock etc

This is very common indeed, possibly the second most common Volvo Haldex fault after the p1889 issue. Often these scrabbling Volvos gets passed from pillar to post trying to find anyone to resolve it, and often the previous messing about has caused more problems along the way!

Quite simply, the very first test which should be done with this problem –

UNPLUG THE HALDEX ECU, LEAVE FOR 20 MINUTES, THEN DRIVE TO SEE IF THE SCRABBLING ISSUE STOPS:-

P1889-74 and 7A error description, diagnosis and resolution. (GEN 2 + 3 ONLY)

It is often misunderstood and causes those with Gen 2 and Gen 3 Haldex systems expensive misdiagnosis. To quote the manufactures descriptions:-

“Oil Pressure Pump Performance. Mechanical Failures. Actuator slipping”.

Condition = The Differential electronic module (DEM) checks the oil pressure in the Haldex clutch using an oil pressure sensor.

When the engine speed exceeds 500 rpm, an initial pressure builds up in the clutch via an electric feed pump. The diagnostic trouble code (DTC) is stored if the control module detects that:

◾ Initial pressure not reached within 2-4 minutes.

◾ Four wheel drive is thus disengaged.

Possible Causes

◾ Pressure sensor is not functioning. (contacts problem or the sensor itself)

◾ Damaged feed pump. (e.g. there is no pressure being created although motor is running)

◾ Too low oil volume in clutch. (thus no pressure being made)

◾ Internal leak in the clutch. (thus the pressure is being lost somewhere)

This is a problem we have come across a few times now, the description is somewhat misleading! It describes it as “Mechanical Failure Actuator Slipping”, but this is in the contexts of the pump, not the clutch itself. Basically it is running the pump, but it isn’t making the required pressure to turn off, thus it is some kind of internal leak, or no/low fluid etc.

P0961-62 = Pressure Control Solenoid A – Control Circuit Range Performance – Algorithm Based Failure (Generation 4 Haldex Units)

This is a common issue with Volvos! Often the fault will present itself after the vehicle has been driven for 10 to 20 Minutes, then as the vehicle slows down for example to a junction or to stop, the message “anti skid service required”.

P1889-14 = Oil Pressure Pump Performance – Circuit Short To Ground or Open Circuit

This is the most common issue with the Generation 4 Haldex systems on Volvo vehicles from 2008 to 2015, it is very common around 40k to 60k miles on the clock. Some scanners will just read it as “P1889 Pressure Pump Performance”, but a decent scan tool will give you the status bytes at the end “14” which tells you it is open circuit etc. Often this code will clear, but give it 3 days, 3 weeks or 3 months it’s always back! Just tapping the pump with a spanner often makes a totally non working pump spring back into life briefly.

Volvo 31256757 Generation 4 Haldex Pump S60 S80 V70 XC60 XC70 XC90

Volvo 31256757 Generation 4 Haldex Pump S60 S80 V70 XC60 XC70 XC90

Volvo, Ford, Land Rover, Range Rover – Gen 4 Oil & Filter Service Kit

Volvo, Ford, Land Rover, Range Rover – Gen 4 Oil & Filter Service Kit

P1889-71 error description, diagnosis and resolution. (GEN 5 ONLY

The DEM checks the performance of the Haldex pump, the control module compares the current load (amps) when driven at various voltages against its predefined parameters saved within its computer memory. Possible causes are listed as “Internal Leak in the Oil Pressure Pump” or “Damage to Oil Pressure Pump”

P1889-18 TSB Technical Service Bulletin (GEN 5 ONLY

There was a TSB raised within the dealerships for P188918 with document reference number TJ28879. It states:-

“The fault-tracing for DTC DEM-P188918 is changed/modified in order to avoid unnecessary parts replacement (DEM-P188918 does not often need a parts replacement). The DTC can be set if air has entered the all wheel drive clutch package, which can happen during oil filling. This can be remedied by air-bleeding the system (ventilation of the all wheel drive clutch package).” APPLIES ONLY TO GEN 5 HALDEX SYSTEMS!!!

- Remove oil pump from AOC (Active On demand Coupling) and inspect the strainer.

- Clean strainer with lint-free cloth, do not use any cleaning liquids (this can contaminate the oil).

- Clean pump sump in AOC, do not use any cleaning liquids (this can contaminate the oil).

- Assemble cleaned pump to AOC.

- Fill up with new oil to correct oil level in AOC according to VIDA.

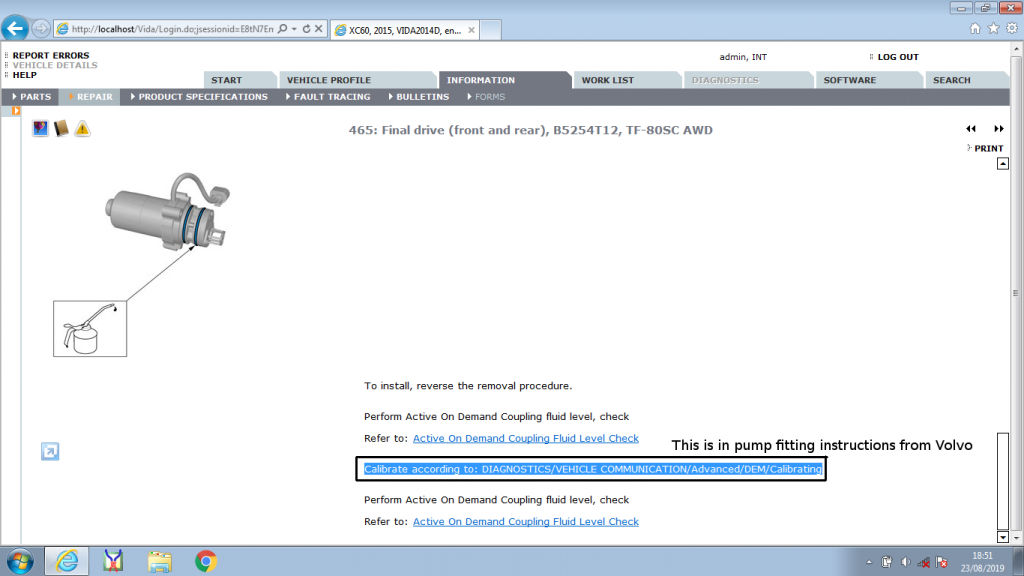

- Perform a calibration using VIDA.

- Check the oil level. If the oil level is low, check the all wheel drive clutch pack for leaks. Then top up with oil (This is also the first step in VIDA’s fault-tracing for DTC DEM-P188918).

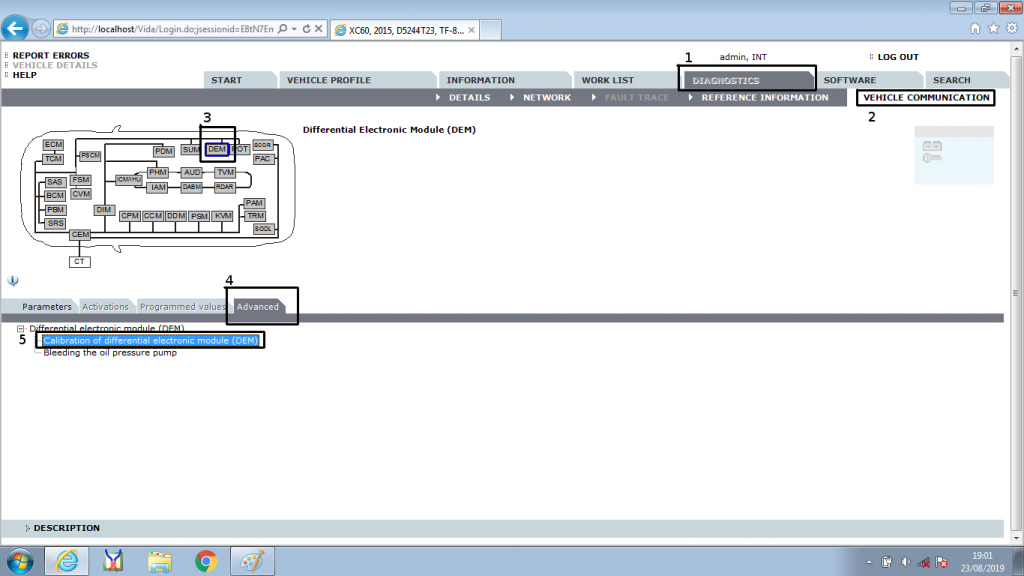

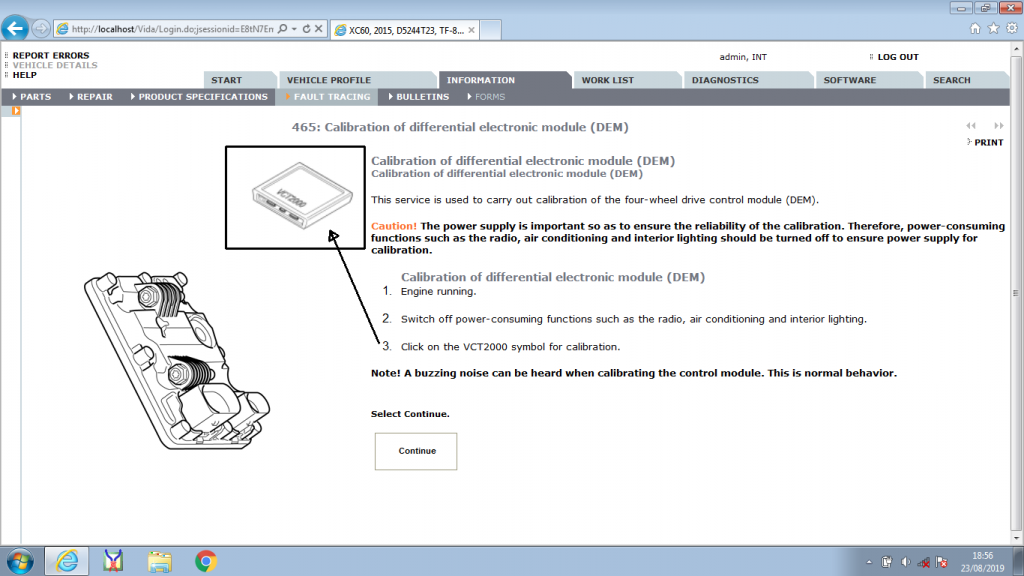

NOTE: The oil level in the all wheel drive clutch package is very important for the function of the all wheel drive. - Do an air-bleeding of the system (ventilation of the wheel drive clutch package) by doing an calibration of DEM. Go to; DIAGNOSTICS\VEHICLE COMMUNICATION\DEM\Advanced\ Calibration of Differential Electronic Module (DEM).

- If this does not remedy the fault, change the oil pressure pump