Land Rover Freelander 2 FL2 Range Rover Evoque Haldex Fault Finding Problems & Solutions

What Haldex System is fitted to which Land Rover Range Rover Applications?

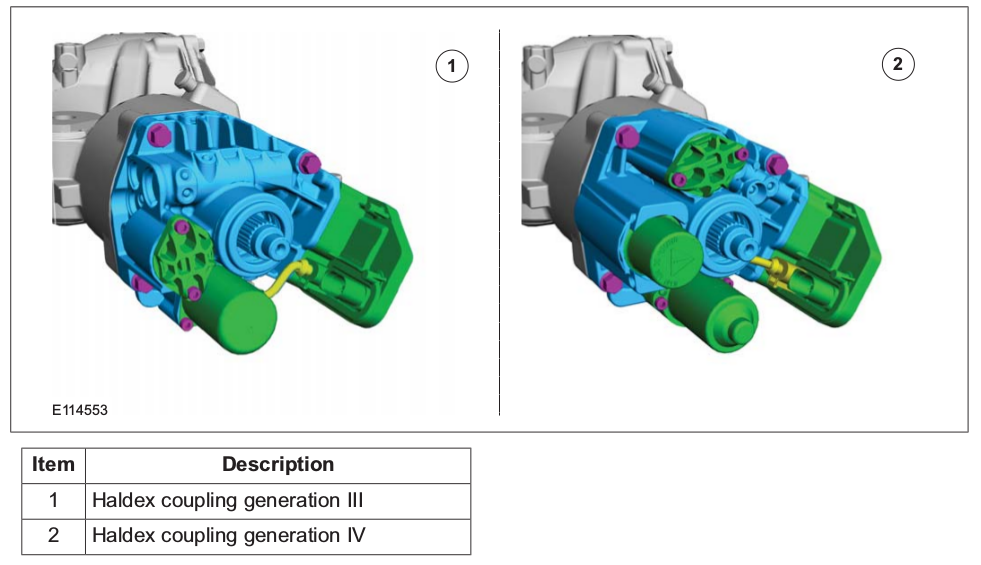

- Land Rover Freelander 2 L359 2007 – 2008 upto VIN/Chassis Number (last 8 digits) 8H999999 and 7H999999 = Gen 3

- Range Rover Evoque L538 2011 2012 2013 2014 2015 before VIN (last 8 digits) FH99999 = Gen 4

- Land Rover Freelander 2 L359 2009 – 2015 after VIN (last 8 digits) 9H000001 onwards = Gen 4

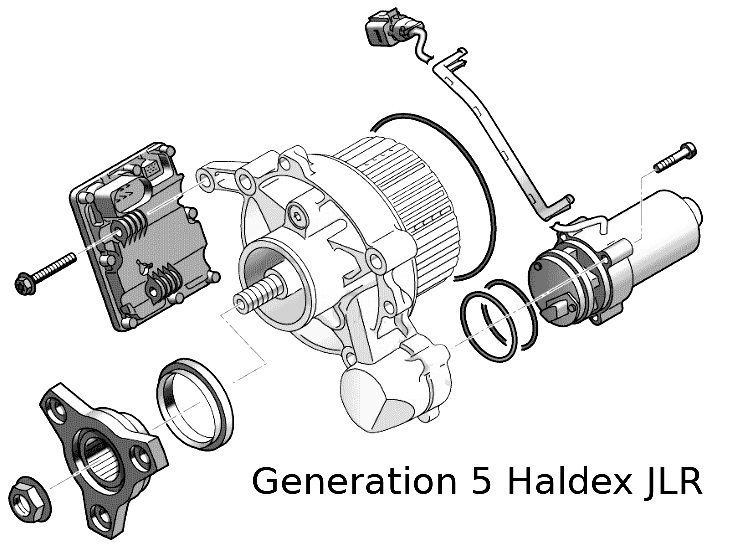

- Land Rover Discovery Sport L550 2015 to 2017 HSE, HSE Luxury, SE = Gen 5

- Range Rover Evoque L551 2016 to 2018 Autobiography, HSE, HSE Dynamic, Landmark Edition, SE, SE Dynamic, SE Premium = Gen 5

Range Rover Evoque and Land Rover Discovery Sport are fitted with either “Efficient Driveline” which is Generation 5 Haldex or “Dynamic Driveline” which is made by GKN Driveline, not a Haldex system.

Full List of Fault Codes for Land Rover / Range Rover Haldex RDCM

- P0560-17 System Voltage – circuit voltage above threshold

- P0602-54 Powertrain Control Module Programming Error – missing calibration

- P0607-49 Control Module Performance – internal electronic failure

- P0666-11 PCM / ECM / TCM Internal Temperature Sensor Circuit – circuit short to ground

- P0666-15 PCM / ECM / TCM Internal Temperature Sensor Circuit – circuit short to battery or open

- P0667-27 PCM / ECM / TCM Internal Temperature Sensor Range/Performance – signal rate of change above threshold

- P0748-14 Pressure Control Solenoid A Electrical – circuit short to ground or open

- P0748-1D Pressure Control Solenoid A Electrical – circuit current out of range

- P0932-11 Hydraulic Pressure Sensor Circuit – circuit short to ground

- P0932-15 Hydraulic Pressure Sensor Circuit – circuit short to battery or open

- P0937-11 Hydraulic Oil Temperature Sensor Circuit – circuit short to ground

- P0937-15 Hydraulic Oil Temperature Sensor Circuit – circuit short to battery or open

- P0938-27 Hydraulic Oil Temperature Sensor Range/Performance – signal rate of change above threshold

- P0961-62 Pressure Control Solenoid A Control Circuit Range/Performance – signal compare failure

- P1889-12 Oil Pressure Pump Performance – circuit short to battery

- P1889-14 Oil Pressure Pump Performance – circuit short to ground or open

- P1889-49 Oil Pressure Pump Performance – internal electronic failure

- P1889-74 Oil Pressure Pump Performance – actuator slipping

- P188A-68 Differential Oil Temperature Too High/Too Low

- U0001-00 High Speed CAN Communication Bus

- U0100-00 Lost Communication With ECM/PCM “A”

- U0121-00 Lost Communication With Anti-Lock Brake System (ABS) Control Module

- U0138-00 Lost Communication With All Terrain Control Module

- U0140-00 Lost Communication With Body Control Module

- U0300-00 Internal Control Module Software Incompatibility

- U0300-4A Internal Control Module Software Incompatibility – incorrect component installed

- U0401-68 Invalid Data Received From ECM/PCM – event information

- U0415-00 Invalid Data Received From Anti-Lock Brake System (ABS) Control Module

- U0418-68 Invalid Data Received From Brake System Control Module

- U2101-00 Control Module Configuration Incompatible

- U3002-81 Vehicle Identification Number- invalid serial data received

- U3003-62 Battery Voltage – signal compare failure

Fault Code Lead Common Solutions

(if you don’t have any fault codes, scroll half way down this page)

P1889-14 = Oil Pressure Pump Performance – Circuit Short To Ground or Open Circuit

This is the most common issue with the Generation 4 Haldex systems on Land Rover / Range Rover vehicles from 2008 to 2015, it is very common around 40k to 60k miles on the clock. Some scanners will just read it as “P1889 Pressure Pump Performance”, but a decent scan tool will give you the status bytes at the end “14” which tells you it is open circuit etc. Often this code will clear, but give it 3 days, 3 weeks or 3 months it’s always back! Just tapping the pump with a spanner often makes a totally non working pump spring back into life briefly.

This fault is caused by the brushes and commutator inside the Haldex pumps motor being worn out.

Most vehicles require the prop shaft to be removed in order to get the required space to swap the pump. The whole job takes around 2 to 3 hours by a competent garage. No coding or programming etc is required. There is a Land Rover “TECHNICAL BULLETIN LTB00795NAS1 03 AUG 2015” about this issue, which talks about a software update, but this is not a software issue, it is 100% a faulty pump. No amount of servicing/oil changing will resolve this issue.

P0960 = Pressure Control Solenoid A – Control Circuit – Open

This is caused by either a faulty haldex control unit, often by corrosion inside, or by damage to the N373 Control Valve.

P1889-74 = Oil Pressure Pump Performance. Mechanical Failures. Actuator slipping & P1889-7A = Oil Pressure Pump Performance. Mechanical Failures. Fluid leak or seal failure

This is a problem we have come across a few times now, the description is somewhat misleading! It describes it as “Mechanical Failure Actuator Slipping”, but this is in the contexts of the pump, not the clutch itself. Basically it is running the pump, but it isn’t making the required pressure to turn off, thus it is some kind of internal leak, or no/low fluid etc.

We have come across 3 examples of this where the Haldex has just had previous work elsewhere requiring the front drive flange to be removed (e.g pump replacement or servicing). But when the flange has been reinstalled, a bearing inside the coupling has been dislodged and then reassembled unknowingly incorrectly inside. This completely bends the working piston etc inside the coupling.

P0961-62 = Pressure Control Solenoid A – Control Circuit Range Performance – Algorithm Based Failure (Generation 4 Haldex Units)

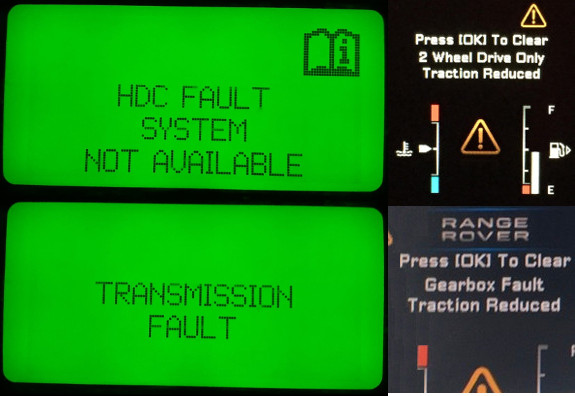

This is a common and difficult issue with Land Rovers! Often the fault will present itself after the vehicle has been driven for 10 to 20 Minutes, then as the vehicle slows down for example to a junction or to stop, the message “Transmission Fault” or “Traction Reduced” pops up. There is a Land Rover “Technical Bulletin LTB00843NAS1 08 Oct 2015” covering this issue, but their documented fix does not work!

We have spent alot of time experimenting with this issue as we have a glut of control units that have this exact fault. Land Rover’s solution is a software update, but we have tried it many times without success. We have confirmed this is a fault on the Haldex Control unit circuit board, by swapping the “faulty units” software onto a new board, which then works flawlessly. Many many hours of experimentation has been invested into this issue, and it has been concluded that it is sometimes a fault on the haldex controller circuit board, and/or a jamming N373 solenoid.

VIN Mismatch U3002-81 Vehicle Identification Number- invalid serial data received

Some RDCM/Haldex Control units are actually uniquely programmed to the individual vehicle, and if swapped onto another vehicle with a different VIN/Chassis number it will give an error code and message on the dashboard regarding “Transmission Fault” or “Traction Reduced”. Currently there are no diagnostic tools on the market that will reprogram the VIN number once it has been set. We have found some customers have bought “Service Exchange” Haldex controllers direct from Land Rover Dealers, with the label “Genuine Land Rover Approved Part” on a blue sticker, only to find when they try to use them they are already VIN locked from the original donor vehicle.

It seems that Land Rover themselves do not fully understand the quirks of these units. The VIN locked units have been Gen 3 Haldex units from pre 2009 Freelander, and Range Rover Evoque after 2013. But which are VIN programmed and which are not seems to be random.

U0136-87 or U0136 No communication with Differential Control Module (RDCM)

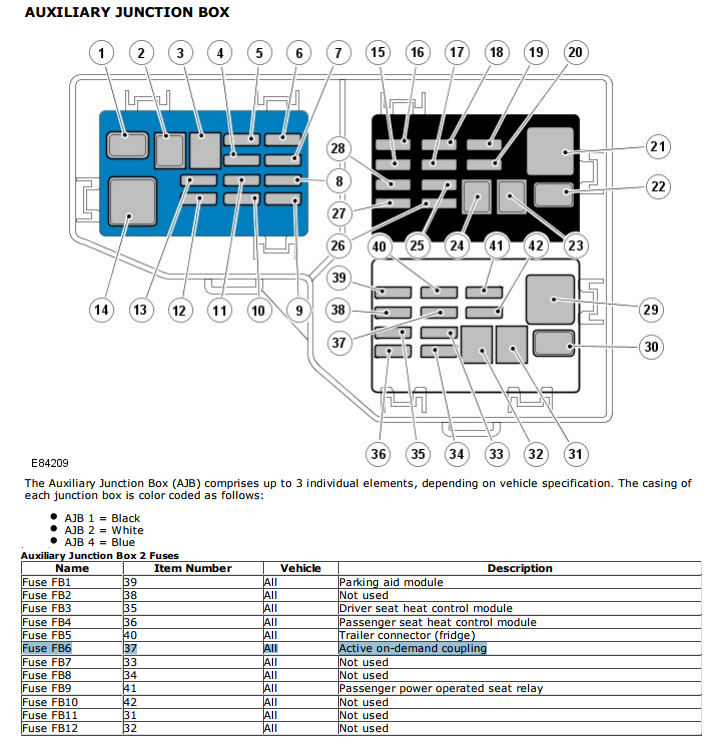

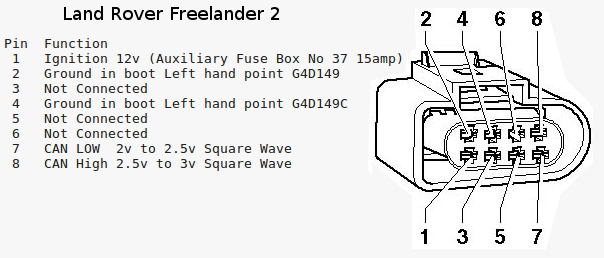

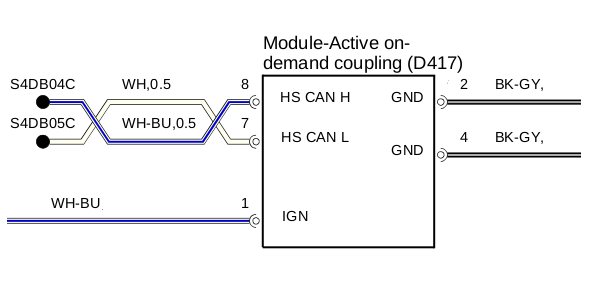

Fault codes are often U0136-00 on the ABS system, U0136 on the BCM, U0136-87 Lost Communication with Differential Control Module Rear on the ATCM. There are a few causes for this fault. Either the wiring to the Haldex controller is corroded under the car somewhere, often it is one of the CAN lines on pins 7 or 8. The fuse is blown for the RDCM/Haldex unit.

The other cause which is the most common is a defective Haldex Control unit. The main issue is the circuit board burns out between the ground inside and the CAN lines, it seems a common issue when the car has been started with a flat battery then jump started.

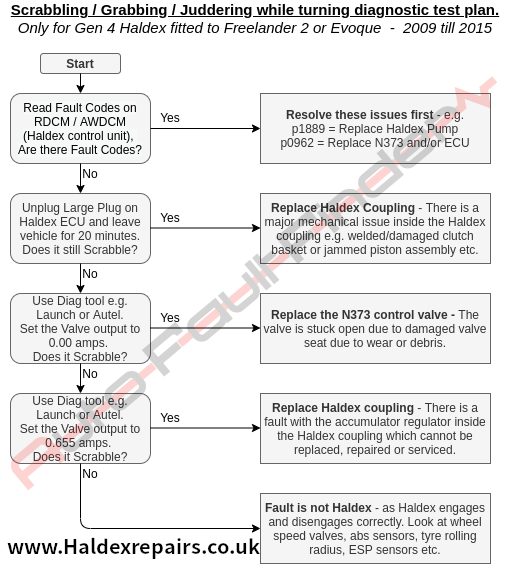

No Fault Codes Stored AND scrabbling or grabbing or skipping or jumping or locked diff sensation going round tight turns, on lock etc.

This is very common indeed, possibly the second most common Land Rover Haldex fault after the p1889 issue. Often these scrabbling Land Rovers gets passed from pillar to post trying to find anyone to resolve it, and often the previous messing about has caused more problems along the way!

Quite simply, the very first test which should be done with this problem –

UNPLUG THE HALDEX ECU, LEAVE FOR 20 MINUTES, THEN DRIVE TO SEE IF THE SCRABBLING ISSUE STOPS:-

The first thing to check though is the N373 Valve. Make sure the valve is working correctly and is not stuck open and doesn’t have damaged valve seats. Unfortunately Jaguar Land Rover have discontinued replacement N373 valves so they are now forever out of stock everywhere. But from our experience, its rarely the N373 valve at fault.

Whilst checking the valve, carry out a service of the coupling. Remove pump, ECU controller and filter, and clean all orifices (galleries) on coupling using an air line and break cleaner, ensuring a good blow out of the oil route between the N373 valve and the filter.

Replace filter cartridge with a genuine one such as Borgwarner and use a good quality Haldex oil such as Febi Bilstein or Volvo branded Haldex Oil. We sell these items and their product links can can be found at the bottom of this page. Do not use chinese copy filters as they do not seal correctly. We also advice not to use Land Rover Haldex oil as we have found it to be of poor quality.

Also at the bottom of this page you will find instructions for removing the prop shaft from the Drive Flange, and the correct oil filling methods for the differential and Haldex Coupling and the correct tightening/ Torque values.

Once you have completed the servicing of the coupling, reinstall it and carry out a thorough road test of the 4×4 system for least 20 – 25 miles. Often the scrabbling disappears straight away because there is air in the Accumulator and hydraulic system as a result of the service, making a “spongy” system, but after 10 to 15 miles or so, the scrabbling comes back.

If the scrabbling does come back (and it probably will), then the problem is most likely the Accumulator which will contain gunk and a damaged bore, preventing the piston from moving all the way back into the correct position, past its pressure blow off point. This leads to an increase in pressure applied to the N373 valve resulting in the scrabbling.

As mentioned earlier, you can not replace the Accumulator, rather you need to replace the entire Haldex coupling. If you were to buy a remanufactured coupling from Land Rover, you will find that the coupling may have a faulty Accumulator, because not even Land Rover themselves can replace or service the Accumulator due to the amount of tension in the spring within the casing (see video below).

If your vehicle is scrabbling or juddering, watch this video!

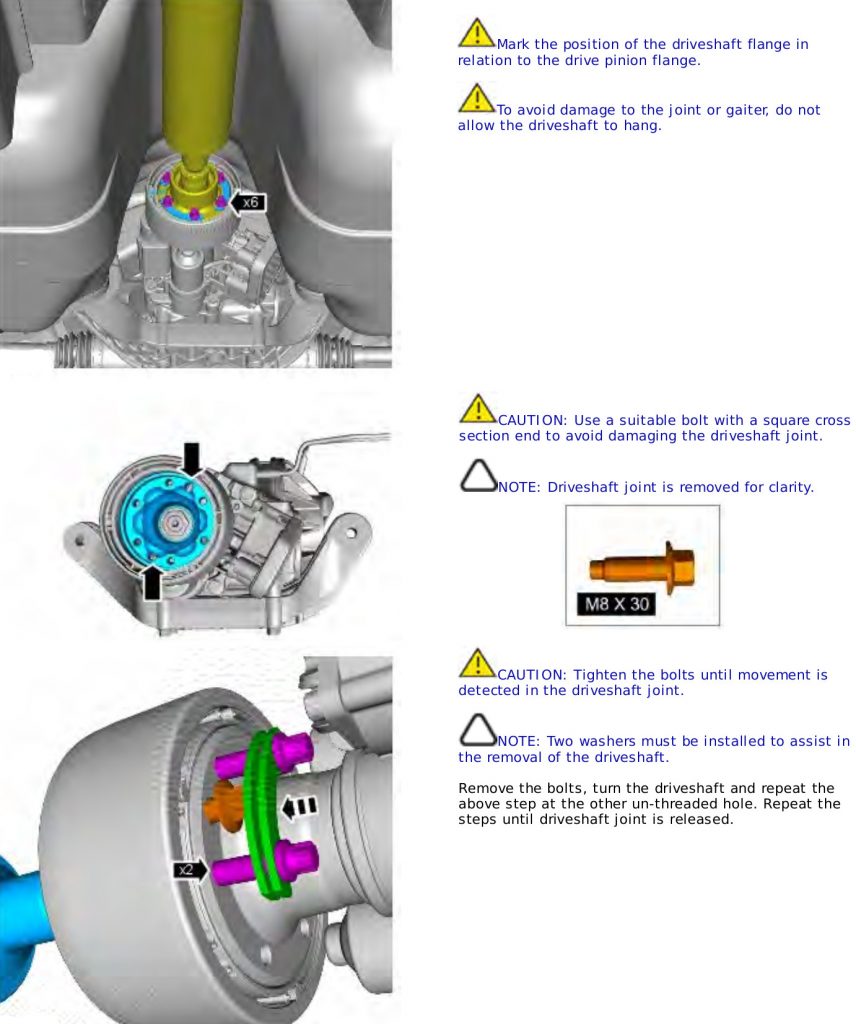

Removing the Propshaft from Drive Flange

To carry out most repairs and servicing normally the prop shaft has to be removed along with the front drive flange from the Haldex coupling. Often people struggle to remove the prop shaft from the flange even though the bolts are removed. The easiest way is to use the existing bolts and plates as per the pictures below:-

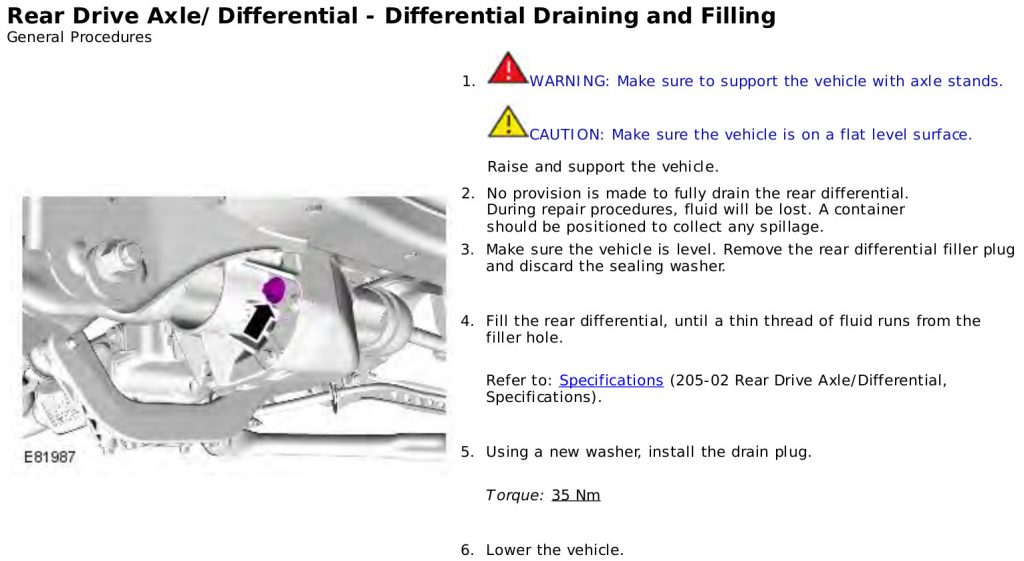

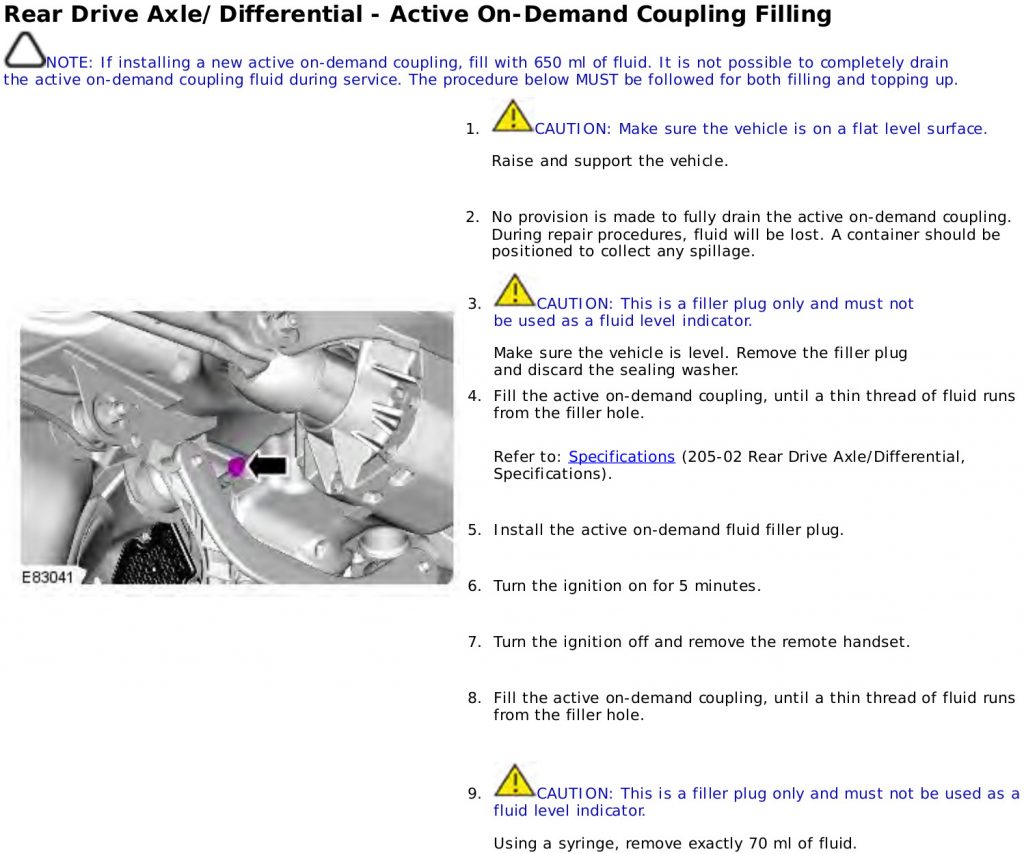

Oil Filling Methods for Differential and Haldex Coupling

Volvo, Ford, Land Rover, Range Rover – Gen 2 & 3 Oil Filter Service Kit

Volvo, Ford, Land Rover, Range Rover – Gen 2 & 3 Oil Filter Service Kit

Volvo, Ford, Land Rover, Range Rover – Gen 4 Oil & Filter Service Kit

Volvo, Ford, Land Rover, Range Rover – Gen 4 Oil & Filter Service Kit

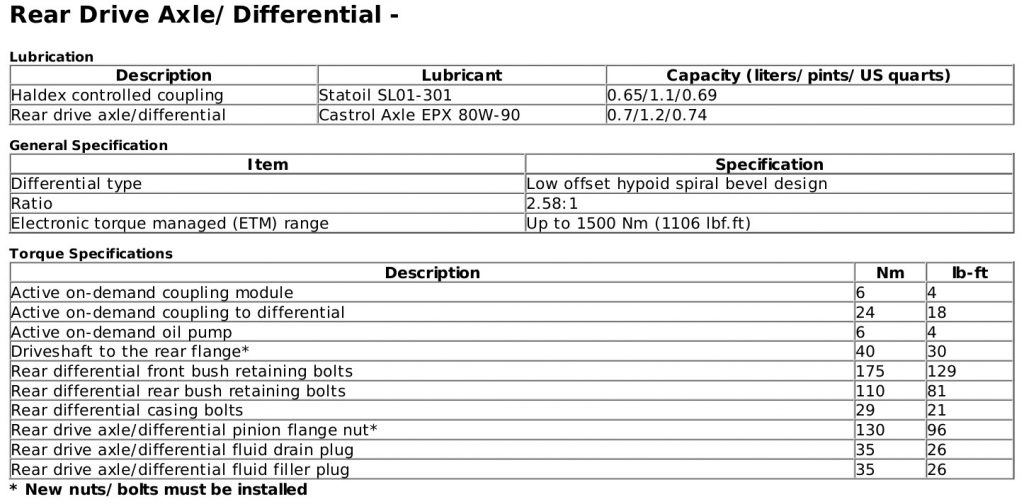

Tightening / Torque Values for Haldex Coupling, Propshaft and Differential in Nm Newton Metres and Lb-Ft Foot Pounds

Part numbers from the Label on the side of the ECU

- hap542 5wp33501-01 (Gen 3)

- hap542 5wp33501-02 (Gen 3)

- hap542 5wp33501-03 (Gen 3)

- hap542 5wp33501-04 (Gen 3)

- hap542 5wp33501-05 (Gen 3)

- hap542 5wp33501-06 (Gen 3)

- hap542 5wp33519-01 (Gen4)

- hap542 5wp33519-02 (Gen4)

- hap542 5wp33519-03 (Gen4)

- hap542 5wp33519-04 (Gen4)

- hap542 5wp33533-01 (Gen4)

- hap542 5wp33533-02 (Gen4)

- hap542 5wp33533-03 (Gen4)

- hap542 5wp33533-04 (Gen4)

- hap542 5wp33533-05 (Gen4)

- hap542 5wp33533-06 (Gen4)

JLR Part Numbers for replacement parts direct from Land Rover

- LR007757 / LR006717 = Generation 3 Haldex Control Unit RDCM

- LR139486 / LR126296 / LR008956 / LR055990 = Generation 4 Haldex Control Unit RDCM

- LR139418 / LR073537 = Generation 5 Haldex Control Unit RDCM

- LR003147 = Haldex Pump for Gen 3, Freelander 2 2007 and 2008

- LR008958 / LR075763 = Haldex pump for Gen 4, Freelander 2 2009 onwards and Evoque pre 2016

- LR051321 = Haldex Pump for Gen 5, Evoque 2016 onwards, Discovery Sport 2016 onwards

- NOT AVAILABLE @ LAND ROVER = Haldex Filter for Gen 3 Freelander 2 2007 and 2008

- LR032298 = Haldex Filter for Gen 4 Freelander 2 2009 onwards and Evoque pre 2016

- LR124825 = Range Rover Evoque 2015 > + Discovery Sport 2015 > LR “Remanufactured” Gen 5 Pump

- LR125175 = Freelander 2 2009 – 2014 + Range Rover Evoque 2012 > LR “Remanufactured” Gen 4 Pump

Software Versions

6G9N-4C045-AF = Freelander 2 2007, 2008 Gen 3 Haldex

6G9N-4C045-AG = Freelander 2 2007, 2008 Gen 3 Haldex

8G9N-4C045-BB = Freelander 2 2007, 2008 Gen 3 Haldex

AG92-4C045-AA = Freelander 2 2009, 2010 Gen 4 Haldex

AG92-4C045-AB = Freelander 2 2009, 2010 Gen 4 Haldex

AG92-4C045-AC = Freelander 2 2009, 2010 Gen 4 Haldex

BH52-4C045-AA = Freelander 2 2011, 2012 Gen 4 Haldex

BH52-4C045-AC = Freelander 2 2011, 2012 Gen 4 Haldex

BJ32-4C045-AC = Evoque 2012, 2013 Gen 4 Haldex

BJ32-4C045-AD = Evoque 2012, 2013 Gen 4 Haldex

BJ32-4C045-AD = Evoque 2012, 2013 Gen 4 Haldex

DH52-4C045-AB = Freelander 2 2013, 2014, 2015 Gen 4 Haldex

EJ32-7B762-CE = Evoque 2014, 2015 Gen 4 Haldex